0086 020 84847938

info@ajaxdent.com

Ajax has a very strict quality management system and quality control process. Our testing methods can effectively test the life, performance, and function of materials. The Ajax quality control team will meticulously execute the process to ensure the quality of each product, providing dental chairs of high quality to create value for customers is our commitment.

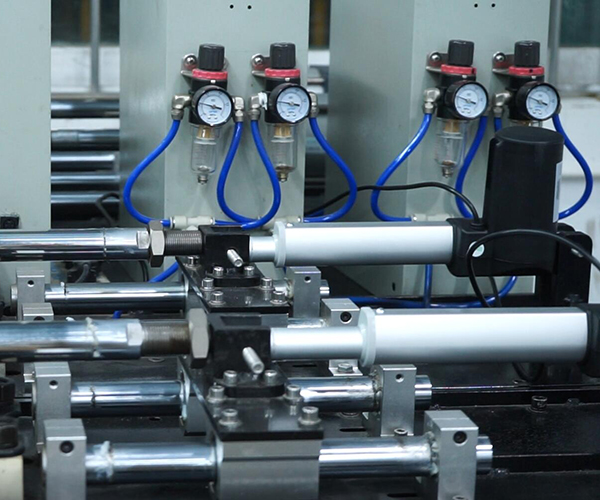

Ajax’s Reliability Lab has advanced reliability test equipment which supports product life simulation tests, stressed tests, acid-resistance tests, alkali-resistance tests, etc.. Every part of our products and the material we use have to go through and pass these tests to ensure the highest quality of our dental chairs.

Starting from the very first step, component and material quality is a key determinant of finished product quality and that is why Ajax inspects all the incoming materials and component parts with the highest standards. Our experienced quality inspectors make sure they are up to the standards to go to the next step.

We use IPQC to ensure that product quality is maintained or improved. We pay attention to every detail of each process, making sure that the component parts are in the best quality.

Every function of the products will be inspected at this part to make sure that each one has an excellent performance. All the outgoing products are carefully checked and cleaned by our engineers before delivery.

We are devoted to bringing the best products to our customers. A top priority of us is to make our customer experience the highest quality with competitive prices. In a best endeavor to quality control, Ajax dental chairs always offer our customers quality dental care.